Imagine this, it’s a fairly slow day in the shop meaning you can take anyone showing up without an appointment. However, does anyone include someone driving a Tesla or one of the newer Toyota Prius models? Would you even consider offering a service?

We understand that many shop owners feel intimidated by electric and hybrid vehicles and wouldn’t even consider troubleshooting. Whether we like it or not, electric vehicles will become more and more common. Currently, there are about 3.3 million electric or hybrid cars in the US, which are 3.3 million reasons for you to prepare your shop for EVs in 2024.

The Difference Between Electric & Hybrid

The most significant difference is that hybrid cars have an ICE (Internat Combustion Engine) that offers a secondary mode of propulsion while the electric vehicle can only run on electricity. In this article, we’ll talk about the electrical components that are presented in both types, so for the sake of integrity, we’ll refer to electric and hybrid vehicles interchangeably.

Let’s Talk Electric Safety

Working with electric vehicles means working with high voltage which is a considerable safety risk. Here are some safety tips to keep in mind.

Wheel Chocks

Electric vehicles are shockingly silent meaning that the engine may be running without you even realizing it. This is installing a wheel chock on at least one wheel is recommended.

Personal Protective Equipment

Your PPE is essential and there are 3 essential items packed with yours:

- Glove bags

- Individual rubber gloves

- A rescue hook

Major EV Components

There are 5 essential EV components that auto shops should be able to service. Take a look at the following:

- Batteries: High voltage DC batteries, typically using nickel-metal hydride, lithium-ion, or lithium polymer technology

- Motor Generator: Available in configurations with either single or dual motors.

- Inverter: This device converts high-voltage DC (direct current) to three-phase AC (alternating current) for the generator. It also increases DC voltage to a higher AC voltage to charge high-voltage vehicle batteries.

- Converter: This component transforms high voltage DC into low voltage to power components like the 12-volt battery, sound system, light bulbs, and OBD2 system.

- IGBTs: Insulated Gate Bipolar Transistors.

Insulation Tests

Just like servicing the major EV components, a future-proof auto shop should be able to handle insulation tests, meaning you need Ohm meters. This ensures all the components are functioning well.

Simply put, you’ll need to check if the voltage in the wires is healthy for each of the main components. The test will highlight dead circuits or shorted wires.

EV Batteries

Before we dive deeper into the different kinds of EV batteries, it’s important to mention a couple of battery cautions:

- Never let a battery overheat.

- Recycle batteries when ready to dispose of them.

This is as basic as it goes. With that out of the way, you should know that each manufacturer uses a different type of battery. As a general auto shop, here are the ones you should be familiar with.

- Cylindrical Cell Batteries: These versatile batteries can be mounted in any orientation and are utilized by Honda, Ford, and now Tesla.

- Regular Prismatic Flat Cells: These batteries must be mounted horizontally and are employed by BMW and Volkswagen.

- Chevy Volt Battery: Featuring a T-shaped design, this battery weighs approximately 600 pounds and includes the coolant and cover.

- Nissan Leaf Pouch Batteries: These batteries, installed beneath the vehicle, consist of two cells connected in series and two in parallel.

- Tesla Battery: Comprising around 400 cells arranged in both series and parallel configurations.

EV Fuses

Fuses in EVs serve the same purpose as in traditional internal combustion engine vehicles, acting as electrical safety devices designed to protect the vehicle’s circuits from damage due to excessive current flow.

These devices regulate current and provide overcurrent protection, ensuring the circuits remain safe.

EV Motors

Think of an EV motor as a regular vehicle’s alternator. These are 100% brushless motors with 3 wire coils and a spinning bar magnet.

Yes, EVs and hybrid vehicles are a fairly new technology but this doesn’t mean they’re impossible to troubleshoot and the more you think about it, the more sense it makes to get familiar with service electric cars.

Evergreen Services You Can Offer to EVs

Many of the services electric vehicles would need, don’t require special training, tools, and equipment different than your current ones.

Tires & Alignment

For example, you shouldn’t worry too much about changing tires or doing alignments to an electric vehicle. EVs wear out tires quickly as they have a lower center of gravity, which contributes to more aggressive driving.

Break Services

Electric vehicles rely on regenerative braking as they capture the vehicle’s kinetic energy, which would otherwise be wasted during deceleration or braking, and convert it into usable energy. In simple auto shop language, this means breaks need to be surfaced and rotors resurfaced more frequently.

Suspension Services

Another common repair involves replacing the suspension, typically necessary after 50,000 to 70,000 miles, often costing customers 7 to 8 thousand dollars. Since the suspension in EVs is similar to that of an S Class Mercedes Benz, repair shops can service these energy-saving cars without needing to acquire new skills.

Heating & Air Conditioning

Without an internal combustion engine, EVs rely on standalone systems for accessories like power steering, heating, and air conditioning. These systems are crucial, as the A/C is responsible for cooling the engine, not just the car’s cabin. These standalone systems need servicing every two years or 20,000 miles to prevent the risk of the car not starting and leaving customers stranded.

Numbers Don’t Lie

Another interesting point is that EV owners, who typically spend around $50,000 on their vehicles, are generally willing to pay for upgrades to wheels, tires, and suspension. Shops also have opportunities to customize EVs by configuring doors to automatically open and close or enabling trunks to open on command.

Don’t get scared by that. Since EVs are usually bought new, they are relatively easy to disassemble for installing upgrades.

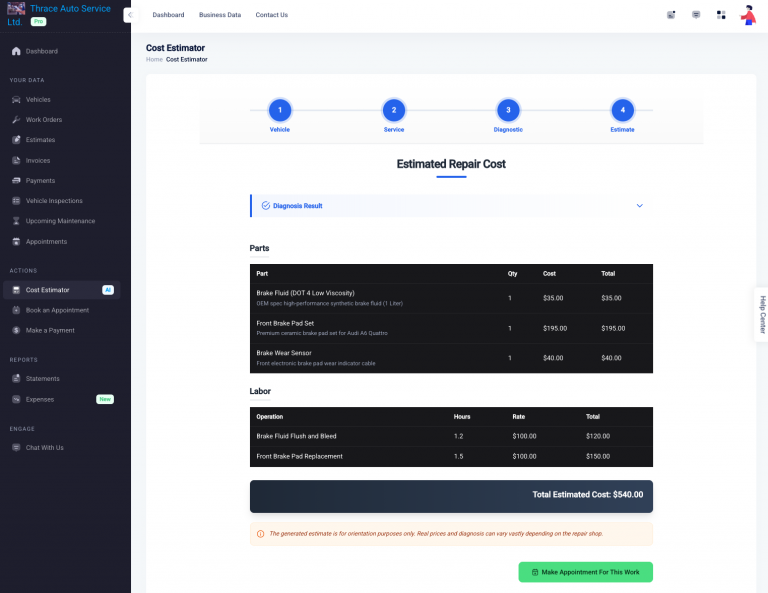

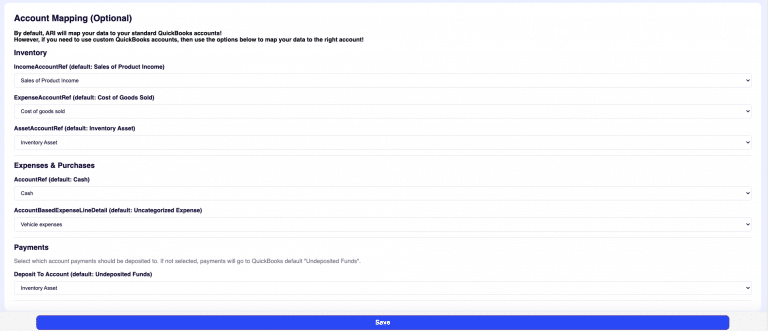

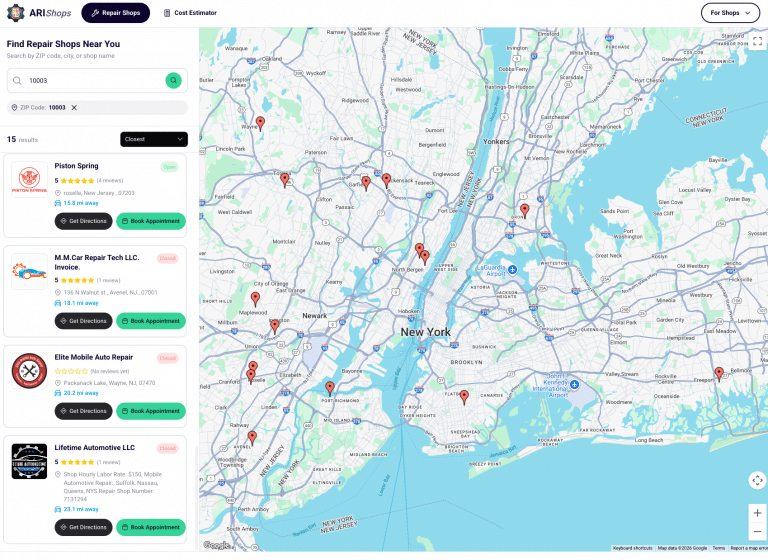

How Auto Repair Shop Software Can Help

Mechanics need to be aware of the risks that come with EVs and familiarize themselves with how they’re made. An auto repair shop software like ARI can help.

Pass New & Updated Info Easily

ARI provides easy access to up-to-date databases that include repair manuals, diagnostic codes, and technical service summaries for all cars including EVs. As a shop owner, you can ensure all your technicians get the latest information with just a few clicks.

Diagnostics & Troubleshooting

ARI can connect to an electric vehicle’s onboard computer system allowing for precise troubleshooting. You only need an OBD2 dongle and the device you’re running ARI’s auto repair shop software. Also, ARI can help you interpret error codes and even suggest solutions.

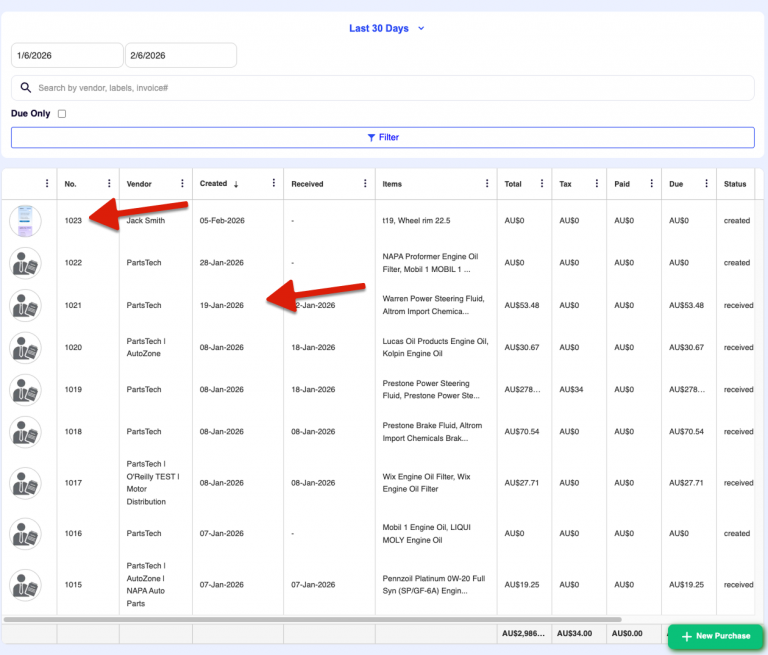

Workflow & Inventory Management

Managing inventory for specialized EV parts is not much different than what you are used but a specialized auto shop repair software can help ensure that all the necessary components are available regardless of the vehicle type that you need them for.

Service History & Communication

Using auto shop software keeps detailed records of each vehicle’s service history which is crucial when it comes to recurring issues and consistent maintenance. Also, there is an option to keep your customers updated with detailed reports and explanations of the service performed.

Auto repair software makes it easier for shops to confidently and efficiently service all kinds of vehicles and makes a difference when it comes to electric cars. If you want to make sure you are prepared for the growing EV market, you can start by downloading ARI today!